-

Sus solucionesSus soluciones

Jungheinrich: proveedor líder de soluciones intralogísticas

- Conocimiento del sector

-

Aplicaciones

-

Automatización y sistemas

Sus soluciones

-

Proceso de automatización

Sus soluciones

-

Tecnología de iones de litio de Jungheinrich

Tecnología de iones de litio de Jungheinrich

Sus soluciones

- Transpaletas y apiladores de iones de litio

- Carretillas elevadoras de iones de litio

-

Productos de iones de litio

Productos de iones de litio

Tecnología de iones de litio de Jungheinrich

-

Referencias de clientes

Sus soluciones

-

BLOG

-

Safety

Sus soluciones

-

ProductosProductos

Jungheinrich: proveedor líder de soluciones intralogísticas

-

Carretillas nuevas

Carretillas nuevas

Productos

- AntOn by Jungheinrich

-

Carretillas de alquiler

Carretillas de alquiler

Productos

- Carretillas de ocasión

- Sistemas automatizados

-

Productos Energéticos

Productos Energéticos

Productos

-

Estanterías industriales

Estanterías industriales

Productos

-

Estanterías estáticas para palets

Estanterías estáticas para palets

Estanterías industriales

-

Estanterías dinámicas para palets

Estanterías dinámicas para palets

Estanterías industriales

- Estanterías estáticas para cargas pequeñas

- Estanterías dinámicas de cargas pequeñas

-

Almacenaje de cargas largas

Almacenaje de cargas largas

Estanterías industriales

- Almacenaje compacto tipo shuttle

- Estantería de bases móviles

-

Estanterías estáticas para palets

- Construcciones especiales

- Radiotransmisión de datos

-

Carretillas nuevas

-

Automatización y sistemasAutomatización y sistemas

Jungheinrich: proveedor líder de soluciones intralogísticas

-

Proveedor de sistemas

Automatización y sistemas

- Robots móviles

- Almacén automático de palets

-

Almacén automático de piezas pequeñas

Almacén automático de piezas pequeñas

Automatización y sistemas

-

PowerCube de Jungheinrich

Automatización y sistemas

-

Estanterías y sistemas de almacenaje

Estanterías y sistemas de almacenaje

Automatización y sistemas

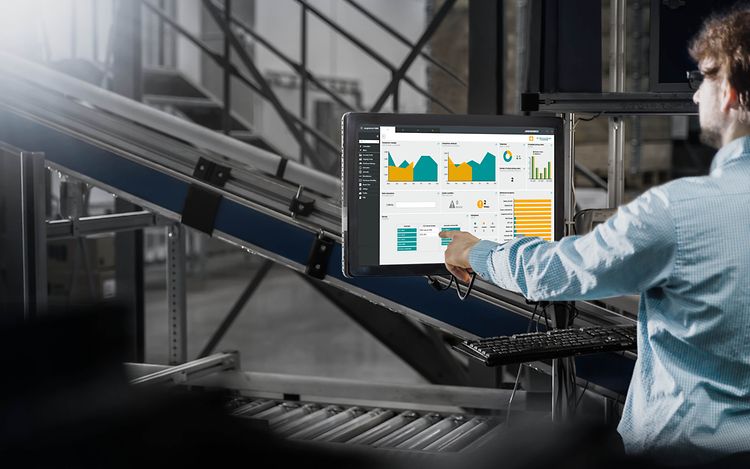

- Productos digitales y soluciones de software

-

Proveedor de sistemas

-

ServicioServicio

Jungheinrich: proveedor líder de soluciones intralogísticas

-

Carrera

-

Sobre nosotrosSobre nosotros

Jungheinrich: proveedor líder de soluciones intralogísticas

-

El Grupo Jungheinrich

Sobre nosotros

-

Prensa

- Innovación & Inspiración

- Historias

- RSC

-

Delegaciones

Sobre nosotros

-

Condiciones generales

Sobre nosotros

-

Buscador de ubicaciones

Sobre nosotros

-

El Grupo Jungheinrich

-

Tienda onlineTienda online

Jungheinrich: proveedor líder de soluciones intralogísticas